المنتجات الساخنة

Mineral and Technological Features of

网页2021年3月24日 Mineralogical studies have established that the main iron-bearing mineral is hematite, which contains 69.02 to 70.35% of iron

Contact

Iron Bridge Magnetite Project, Australia Mining Technology

网页2020年11月2日 The plant will employ the KB 63-130 type gyratory crushers, which will be the largest crushers in the country. The crushers will be used to process raw iron ore

Contact

Processing Citic Pacific Mining

网页2023年5月18日 Processing. Sino Iron’s processing plant is where we transform the magnetite ore into high quality, premium magnetite concentrate. This is the heart of our

Contact

Poltava Ferrexpo

网页The mine is an open-pit operation, whereby the Group's excavators and haul trucks operate around the clock to supply high-quality magnetite iron ore to the Group's processing

Contact

Iron ore magnetite processing alsglobal

网页Magnetite processing. The increased worldwide demand for steel in recent decades has led to an increase in the exploitation of magnetite iron ore deposits as an alternative to

Contact

The Efficient Improvement of Original Magnetite

网页2021年6月17日 Magnetization roasting followed by magnetic separation is considered an effective method for recovering iron minerals. As hematite and magnetite are the main concomitant constituents in iron ores, the

Contact

Developments in the physical separation of iron ore:

网页2015年1月1日 The annualized plant results demonstrated that an iron ore concentrate containing 68.4% Fe could be produced using the flow sheet from run-of-mine ore

Contact

Processing of Magnetite Iron Ores–Comparing

网页2009年1月1日 The results of a theoretical option study for high capacity processing of a hard, fine-grained silica-rich magnetite ore is presented in this , with the emphasis on comminution circuit

Contact

Pelletization of synthesized magnetite concentrate obtained

网页2020年9月1日 The scarcity of high-grade iron ore resource and availability of the considerable quantity of low-grade iron ore fines, banded hematite quartzite (BHQ) ore in

Contact

Mechanisms in oxidation and sintering of magnetite iron ore

网页2008年4月9日 Magnetite iron ore pellets are produced by agglomerating moist, finely ground magnetite concentrate together with a binder in balling drums or balling discs to

Contact

Developments in the physical separation of iron ore:

网页2015年1月1日 The annualized plant results demonstrated that an iron ore concentrate containing 68.4% Fe could be produced using the flow sheet from run-of-mine ore containing 29.1% Fe, at a mass yield to the iron concentrate of 34.8%, an iron recovery of 81.7%, and a tailings grade of 8.2% Fe. and lower operating costs, some subeconomic iron ores

Contact

Magnetite: South Australia’s potential EnergyMining

网页2 天之前 The iron oxide mineral magnetite as Fe 3 O 4 has a mass percent of 72.36% Fe and 27.64% O and typically occurs as a natural ore containing 15–40% Fe. Historically hematite direct shipping ore (DSO) has been the preferred source of iron ore globally, with significant resources located on several continents, including Australia in the Hamersley

Contact

Adding value to iron ore, at a cost: Australia’s magnetite

网页2021年2月23日 Fortescue has previously said that Iron Bridge is a relatively simple magnetite operation compared to others in Western Australia. RBC analyst Kaan Peker pointed out in a research note that Fortescue had invested and tested more at Iron Bridge to "develop the process versus other Australian magnetite mines that have struggled."

Contact

Iron ore magnetite processing alsglobal

网页Magnetite processing. The increased worldwide demand for steel in recent decades has led to an increase in the exploitation of magnetite iron ore deposits as an alternative to hematite DSO ores. Magnetite concentrate is a higher-grade product than hematite and very desirable as a smelter feed. However, the caveat for this superior product is

Contact

New dry iron ore processing technology developed

网页2016年5月26日 New dry iron ore processing technology developed. Ben Creagh May 26, 2016, 9:24 am. The mine tailing dam spill at BHP and Vale’s Samarco iron ore operations last year killed 19 people and had

Contact

Iron processing Ores, Smelting, Refining Britannica

网页iron processing Iron processing Ores, Smelting, Refining: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine. The most widely distributed iron-bearing minerals are

Contact

Magnetite an overview ScienceDirect Topics

网页Magnetite Circuits Control. Dilip Kumar, Deepak Kumar, in Sustainable Management of Coal Preparation, 2018. Abstract. Magnetite is widely used in most dense-medium processes in the coal industry because of its higher specific gravity, stability in suspension, lower viscosity, and easy availability, recovery and reuse. To keep the suspension at the

Contact

How to Recover Iron from Magnetite: 4 Methods and Stages

网页2023年4月7日 Magnetite is the main mineral in iron ore beneficiation, which has industrial value and is mined in large quantities. Here we will introduce the beneficiation method and process of magnetite ore in detail. What is magnetite? Magnetite is an iron oxide ore, which belongs to the equiaxed crystal system, and its chemical formula is Fe 3 O 4. The

Contact

Ore Beneficiation an overview ScienceDirect Topics

网页E. Donskoi, J.R. Manuel, in Iron Ore, 2015 Abstract. To evaluate an iron ore resource, develop processing routines for iron ore beneficiation, and understand the behavior of the ore during such processing, extensive mineralogical characterizations are required.For calculating mineral associations, mineral liberation, grain size and porosity distribution,

Contact

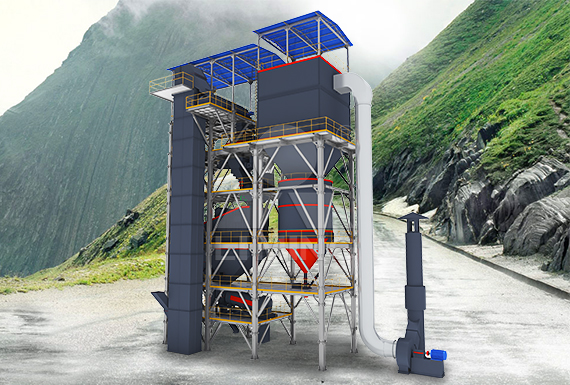

Iron Ore Processing,Crushing,Grinding Plant Machine

网页1. Magnetite ore stage grinding-magnetic separation process The stage grinding-magnetic separation process mainly utilizes the characteristics of magnetite that can be enriched under coarse grinding conditions, and at the same time, it can discharge the characteristics of single gangue, reducing the amount of grinding in the next stage.

Contact

Pelletization of synthesized magnetite concentrate obtained

网页2020年9月1日 The scarcity of high-grade iron ore resource and availability of the considerable quantity of low-grade iron ore fines, banded hematite quartzite (BHQ) ore in mines (mostly in Bihar, Odisha, Madhya Pradesh, and Karnataka), has to lead the way to beneficiate and utilize the concentrate as pellet feed for the steelmaking process.

Contact

China Iron Ore Processing Plant, Iron Ore Processing Plant

网页China Iron Ore Processing Plant manufacturers Select 2023 high quality Iron Ore Processing Plant products in best price from certified Chinese Mining Equipment, Mining Machine suppliers, wholesalers and factory on Made-in-China Magnetite Iron Ore Processing Equipment Beneficiation Plant. US$ 5000-10000 / Piece. 1 Piece (MOQ)

Contact

Razorback Iron Project, Australia Mining Technology

网页2021年7月21日 The proposed processing method has an estimated recovery rate of 16% based on a plant throughput of 12.8Mtpa to produce up to 68.5% iron (Fe) concentrate. Infrastructure of Razorback iron ore project The project site will be accessible via a new 44km-long access/haul road from the Barrier Highway.

Contact

Processing Citic Pacific Mining

网页2023年5月18日 Processing. Sino Iron’s processing plant is where we transform the magnetite ore into high quality, premium magnetite concentrate. This is the heart of our operation at Sino Iron. Before the ore arrives at the processing plant via the conveyor, it’s already been reduced down at the in-pit crushers to roughly the size of house bricks.

Contact

Iron Processing Equipment, Process Flow, Cases JXSC

网页2019年8月23日 The former mainly selects magnetite ore, and the latter is mainly used for sorting hematite, mixed iron ore and weak magnetic ore. 6.2 Magnetic separation cation reverse flotation process The grade of iron concentrate increased from 65.55% to 38.89%, the silica content decreased from 8.31% to 3.90%, and the iron recovery rate was over

Contact

(PDF) The Study of Pelletizing of Mixed Hematite and Magnetite Ores

网页2019年1月11日 The heat hardening by oxidation is a process commonly used in iron ore pelletization process. The green pellets are fired in induration machine using Corex gas at JSW Steel Limited Pellet Plant.

Contact

Optimising Western Australia Magnetite Circuit Design

网页2023年7月20日 Optimising Western Australia Magnetite Circuit Design D David1, M Larson2 and M Li3 1. FAusIMM, Process Consultant, AMEC Minproc, Level 14, 140 St Georges Terrace, Perth WA 6000. Email: dean.david@amec 2. Senior Process Engineer, Xstrata Technology, 5th Floor, 509 Richards Street, Vancouver BC, V6B 2Z6,

Contact

Effect of Particle Size Distribution and Type of Mineral

网页2023年7月24日 In the Chadormalu plant, a retention time of 4.5 minutes in the mill was associated with the highest Blaine number as well as the least recovery of phosphorous minerals. Keywords : Blaine number, Specific surface, Grain size distribution curve, Davis tube test 1. Introduction The concentrate of iron ore processing plants is often in the form of

Contact

Poltava Ferrexpo

网页The mine is an open-pit operation, whereby the Group's excavators and haul trucks operate around the clock to supply high-quality magnetite iron ore to the Group's processing plant. In 2021, the total volume mined at Poltava was approximately 80 million tonnes, including 17 million tonnes of high grade iron ore for processing.

Contact

Magnetite (Iron Oxide Fe3O4) Magnetite Supplier LKAB

网页LKAB Minerals mines and processes the natural mineral magnetite from which a pure, dried and fine milled powder is made. Owning the source and processing plant ensures our customers a long-term, reliable source of consistent quality material. Our dried fine powdered iron oxide is ferri-magnetic, greyish-black in colour, and thermally and

Contact