المنتجات الساخنة

A Technical and Economic Comparison of Ball Mill Limestone

网页2021年10月13日 A pilot-scale Loesche VRM was used to determine the power required to grind 100 t/h of the same limestone as used at Kusile (work index of 12 kWh/t) with a top size of 19 mm to a 85% and 95% passing 45 µm product. A significant power saving of

Contact

Ball Mill Particle Grinding Union Process

网页The CL-5 Stirred Vertical Ball Mill for Limestone Grinding is a smaller version of the production sized CL Series Mills. It is ideal for research, scale-up and small-scale

Contact

A study of the grinding of magnetite/limestone mixture in a

网页2021年9月1日 Moreover, optimizing ball filling ratio and mill speed appropriately by the AR method, the residence time of feed in the grinding chamber could be reduced and the

Contact

Analysis of grinding kinetics in a laboratory ball mill using

网页2019年11月1日 In this study, to determine the grinding parameters of the specific rates of breakage and a primary breakage distribution, the Mill used in the grinding experiment

Contact

(PDF) Grinding in Ball Mills: Modeling and Process

网页2012年6月1日 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more

Contact

Ball Mills 911 Metallurgist

网页2017年2月13日 Ball Mill Grinding P80 Size. The mesh of grinding usually lies between 48 and 200 mesh. On account of their size in relation to that of the bubbles, particles larger than 48 mesh generally have too great a

Contact

Ball mill simulation in wet grinding using a tumbling mill and

网页2004年6月25日 Actual ball motion in the suspension in the mill was observed through a transparent mill lid made of acrylic acid resin at different solid concentrations and the

Contact

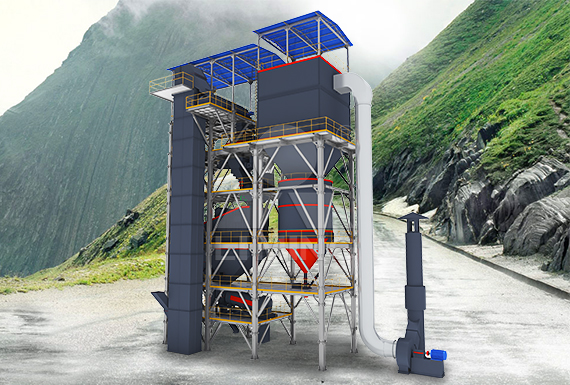

Suitable FGD limestone mill, low investment in

网页2023年2月15日 The limestone powder for FGD is a minimum of 90% passing 325 mesh. Transportation: deliver the limestone to grind the purchased limestone fragments with particle size less than 20mm in the

Contact

Limestone Mill for Limestone Powder Grinding

网页Limestone can be made into limestone powder by treatment of limestone crusher and limestone grinding mill. Limestone powder can produce quicklime by calcination. Quicklime can be widely used for

Contact

Particle size distribution and structural changes in limestone

网页2013年1月1日 This study investigates structural and morphological changes in limestone particles ground in a planetary ball mill. The grinding tests were carried out as a function

Contact

Size Reduction and Energy Requirement ScienceDirect

网页2016年1月1日 The flowsheet considered was dry open circuit crushing and wet rod and closed circuit grinding ball mill grinding. The internal diameters of both rod and ball mills were 2.5 m and a throughput of 100 t/h was initially expected. Estimate the total energy and power required for grinding by the rod and ball mills.

Contact

Energy-Model and Life Cycle-Model for Grinding

网页2022年5月23日 search work was the examination of main grinding parameters of the limestone particles to determine an empiric energy-model. Dry and wet grinding experiments have been carried out with a Bond mill and a laboratory stirred ball mill. During the grinding processes, the grinding time and the filling ratio have been adjusted.

Contact

How Many Balls in a Ball Mill? JXSC Machine

网页2019年12月19日 During the running-in process, the amount of steel balls is added for the first time, which accounts for 80% of the maximum ball load of the ball mill. Steel ball sizes are Φ120㎜, Φ100㎜, Φ80㎜, Φ60㎜, Φ40

Contact

Ground Calcium Carbonate / Limestone Hosokawa Micron Powder Systems

网页The Mikro Pulverizer HammerScreen Mill needs less air (less ancillary equipment) than the ACM and is a lower cost options for the coarser grind Calcium Carbonate products. For ultra-fine (D50 < 5 µm) milling, the Hosokawa Alpine Super Orion Ball Mill and Air Classifier are the best option. These units come in a variety of sizes to meet your

Contact

Bond Work Index an overview ScienceDirect Topics

网页The ball mill work index laboratory test is conducted by grinding an ore sample prepared to 100% passing 3.36 mm (6 mesh) to product size in the range of 45-150 µm (325-100 mesh), thus determining the ball mill work index (Wi B or BWi). The work index calculations across a narrow size range are conducted using the appropriate laboratory work

Contact

Limestone mill, Limestone grinding mill All industrial

网页vertical for powders for limestone. Rotational speed: 67, 120, 100, 83 rpm. Output: 3 t/h 50 t/h. Motor power: 55, 90, 160, 280 kW. MTW-Z European Trapezium Mill Mature technology, Advanced idea, High productivity MTW-Z European Trapezium Mill is new product researched and developed by LIMING based on ordinary European type

Contact

How to make limestone powder using a ball mill? LinkedIn

网页2023年3月16日 Grind the limestone rocks: Run the ball mill for several hours, until the limestone rocks have been ground into a fine powder. The longer you run the ball mill, the finer the limestone powder will be.

Contact

What is the best limestone grinding mill? gkmill

网页2022年6月15日 It is an innovation and upgrade on the R-type Raymond mill. It has a number of independent research and development patented technologies. The indicators of the product are greatly improved compared with the R-type machine. It is widely used in the grinding and processing of non-metallic minerals such as limestone, calcite, fluorite, talc

Contact

Ball Mill Grinding Theory Crushing Motion/Action Inside

网页2017年4月28日 It seems certain, however, that the ball-mill will crush to 200 mesh a considerably greater tonnage when the proper classification is provided. Since in previous tests the mill has crushed 7½ T. per hr. from ¼ in. to 200 mesh, it seems possible that it will crush at least 8 T. per hr. from 48 to 200 mesh.

Contact

en/grind limestone to mesh.md at main sbmboy/en

网页英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Contact

Types of limestone grinding mill LinkedIn

网页2018年10月15日 It has two standards: one is 250 mesh through 90, and the second is 325. Through the screen 90; Guilin Hengda Mining Machinery Co., Ltd is a professional grinding equipment manufacturer, the main

Contact

Design, Construction and Performance Analysis of a 5

网页The laboratory ball mill was designed for grinding limestone, meaning that the work index required for the specific power calculation was assumed to be the work index of limestone, which is 11.6 KWh/t, with a specific gravity of 2.6 g/cm. 3. or 2600 kg/m. 3. The feed size (F. 80) of the ball mill was assumed to be 2 mm (2000 microns).

Contact

Particle size distribution of the feed after the

网页The tests conducted for ball mills [14], cylindrical mills [15,16], and hammer mills [1,17] showed that the particle size distribution curves vary depending on the process and design parameters of

Contact

Necessary Matters About Limestone Powder Grinding

网页2023年2月28日 Three-ring medium-speed micro mill Get Latest Price. The three-ring medium-speed micro milling machine is named because of its design with three grinding rings. It is suitable for making fine and ultra-fine powder. The particle size of limestone powder can be adjusted arbitrarily between 325-2500 mesh, and the output can reach

Contact

(PDF) Grinding in Ball Mills: Modeling and Process Control

网页2012年6月1日 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more rotating cylinders partially filled with grinding balls (made

Contact

(PDF) A quick method for bond work index approximate

网页2017年1月1日 Grinding in a laboratory Bond ball mill occurs according to the fi rst order k inetics. Parameter P 80 of comparative sieve undersize, for all raw materials, changes according to a precise rule.

Contact

Energy Use of Fine Grinding in Mineral Processing SpringerLink

网页2013年12月18日 Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes. This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor. While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s

Contact

Limestone Grinding Mill-mpl Heavy Industry

网页Applications. Limestone powder can be generally divided into coarse powder processing (0-3MM), fine powder processing (20 mesh-400 mesh), and ultrafine powder deep processing (400 mesh-1250 mesh) and micro powder processing (1250 mesh-3250).Four types. Limestone chunks are crushed by crusher to the input fineness of the mill (15mm-50mm).

Contact

sbm/sbm ball mill for grinding limestone mesh.md at main

网页Contribute to sili2023/sbm development by creating an account on GitHub.

Contact

A study of the grinding of magnetite/limestone mixture in a

网页2021年9月1日 A pilot-scale grinding technology of ceramic medium stirred mill was proposed in this study. Based on the specific productivity and grinding efficiency, the appropriate grinding parameters were ascertained as follows: material ball ratio of 0.7, ceramic ball medium size ratio (10 mm: 15 mm: 20 mm = 3:2:5), stirring speed of 110

Contact