المنتجات الساخنة

Selecting Ceramic Grinding Media: Part 1 Theory

网页[Show full abstract] for the talc particles < 20 mu m show higher values of D-f (between 1.25 and 1.35) after wet grinding in a ball mill with ceramic grinding media (Y = 85-86%) than

Contact

The first attempt of applying ceramic balls in industrial tumbling mill

网页2022年4月1日 Compared with steel ball medium, ceramic ball medium has characteristics of good wear resistance, high hardness and low density, and thus can significantly

Contact

Ceramic ball wear prediction in tumbling mills as a grinding media

网页2014年12月1日 This article presents the results of applying a media selection methodology based on a population balance model to a ceramic ball mill; the experimental data were

Contact

3 Types of Grinding Media for Ball Mills FTM

网页2019年12月4日 Spherical ball mill media have an advantage of better crushing effect when impacting large particles because point contact between balls and raw materials makes the materials easy to be

Contact

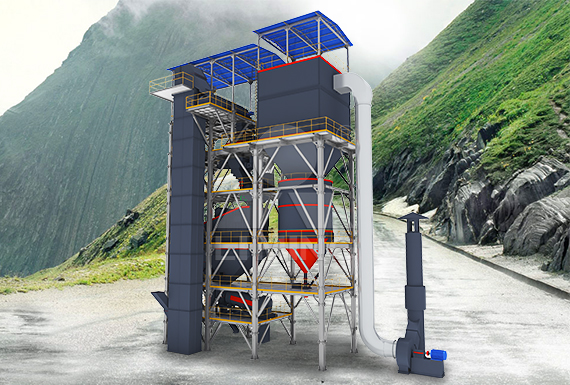

Ceramic Ball Mill For Grinding Materials FTM

网页2022年9月5日 The ceramic ball mill media is ceramic ball. Types of ceramic ball mill. FTM Machinery, as the ceramic ball mill supplier, produced 60T, 40T, 10T, and 0.1-1T ceramic ball mill according to different

Contact

Ceramic Ball Mill Lining BricksGrinding Media Duralox®

网页Duralox 92W lining bricks and Duralox 92W grinding media complement each other’s performance and best results are obtained when both are used together.. PHYSICAL

Contact

(PDF) Grinding in Ball Mills: Modeling and Process

网页2012年6月1日 Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate on a variety of scales, from laboratory to industrial (Monov et al. 2013). The produced

Contact

Ball Mill Grinding Media Options Orbis Machinery

网页A ball mill is a form of grinder that is used to blend or grind materials for use. It is a cylindrical device mainly for grinding material such as iron ores, ceramic raw materials,

Contact

China Ceramic Ball Mill Media, Ceramic Ball Mill Media

网页China Ceramic Ball Mill Media manufacturers Select 2023 high quality Ceramic Ball Mill Media products in best price from certified Chinese Stainless Steel Ball, Ball For

Contact

Ceramin

网页Ceramin has 2 Micronizing Ball Mills with a capacity of grinding 13ktpy of Zircon opacifiers . This is only state-of-the-art grinding Mill in the Middle East and has excellent processing,

Contact

(PDF) Grinding in Ball Mills: Modeling and Process

网页2012年6月1日 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more rotating cylinders partially filled with grinding balls (made

Contact

Choosing Ball Milling Media for Firework Chemical

网页2018年2月15日 Here's a shot of some stainless steel media and ceramic media. The stainless steel must be spark-resistant, non-magnetic steel in the 300-series. Alloys 304 and 316 are the most common stainless

Contact

CannonFuse > Pyro Tools > Grinding Media

网页2023年7月24日 11. $34.95. We offer both Lead-Antimony and Alumina-Ceramic Ball Milling Media. With multiple sizes and shapes available, you're sure to find what you need for your next project. Alumina-Ceramic Media

Contact

Tubular Ball Mills ScienceDirect

网页2016年1月1日 A survey of 40 industrial mills in Australia found that the maximum ball mill diameter in use was 5.34 metres and length 8.84 metres [1]. Autogenous mills range up to 12 metres in diameter. The length-to-diameter ratios indicated in Table 7.1 for ball mills are for normal use, but for primary grinding the ratio could vary between 1:1 and 1.8:1

Contact

Ball Mill an overview ScienceDirect Topics

网页Quantum Nanostructures (QDs): An Overview. D. Sumanth Kumar, H.M. Mahesh, in Synthesis of Inorganic Nanomaterials, 2018 3.6.1.1 Ball Milling. A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball

Contact

Milling Media: Factors for choosing milling media for planetary

网页2020年11月2日 Factors for choosing milling media for planetary and roller ball mills. There are several factors for choosing milling media for planetary ball mills. For instance, the media of choice needs to be a harder material than the sample being processed. Initial and final particle size of the sample is a major consideration

Contact

(PDF) Calculation method and its application for energy

网页2020年2月26日 (PDF) Calculation method and its application for energy consumption of

Contact

Ball Mills : United Nuclear,Scientific EquipmentSupplies,

网页Due to its small barrel diameter and lower impact energy, Ball Mills with small diameter barrels such as our 3 Lb or 6 Lb mills are not suitable for grinding Glass or similar hard materials. Ceramic media is a good choice when you must keep your media contamination to an absolute minimum and is ideal for milling individual chemicals.

Contact

Best milling media and where to buy it? Newbie Questions

网页2015年9月23日 Posted 24 September 2015 07:05 PM. Look for a local metals dealer. They often are buyers of scrap as well. I bought 1/2 and 3/4" brass rod and cut it into slugs using a sawzall and a jig I made to get a consistent length. Thirty pounds of

Contact

Grinding Ball Price, 2023 Grinding Ball Price Manufacturers

网页Material : Alumina. Content : >90%. Usage : Machinery, Chemical, Petroleum, Grind. Processing Type : Rolling Type. More. PINGXIANG KSOURCE CHEMICAL PACKING CO., LTD. Inquiry Basket. 1 / 6. Ceramic Price Ball Price Grinding Machine Price Ceramic Product Price Grinding Equipment Price Steel Ball Price Forged Grinding Steel Ball Cast Iron

Contact

Comparison of grinding media—Cylpebs versus balls

网页2004年11月1日 As a result, for a given charge volume, about 25% more grinding media surface area is available for size reduction when charged with Cylpebs, but the mill would also draw more power. Table 1. Comparative data of physical properties for Cylpebs and balls. Cylpebs ( γ = 7.65 kg/l) Balls ( γ = 7.85 kg/l)

Contact

Ceramic Balls Ceramic Grinding Media Balls Manufacturer

网页Manufacturer of Ceramic Balls Ceramic Grinding Media Balls, Ceramic Ball Mill offered by Synco Industries Limited, Jodhpur, Rajasthan. Synco Industries Limited. Basni, Jodhpur, Rajasthan. GST No. 08AAACS5548J1Z2. Send E-mail. Call 08048971945 86% Response Rate. Home ; About Us ; Our Product Range ;

Contact

Ball Mills Ball Mill Ball Milling Orbis Machinery

网页Steel Ball MillsLined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s. The basic construction of a ball mill is a cylindrical container with journals at its axis. The cylinder is filled with grinding media (ceramic or metallic balls or rods

Contact

Ceramic Ball Mill For Sale Automatic Ceramic Ball Mill

网页Motor Power: 2.2-75 kw. Material: ceramic sand, aluminum slag, limonite, river sand, fly ash, calcite, iron ore, barite, etc. The ceramic ball mill is a kind of ball mill grinder that the liner plate is made of wear-resistant ceramics. It has a small capacity, suitable for small batch production, and it can realize a 24-hour continuous work

Contact

Ball Mills : United Nuclear,Scientific EquipmentSupplies,

网页Due to its small barrel diameter and lower impact energy, Ball Mills with small diameter barrels such as our 3 Lb or 6 Lb mills are not suitable for grinding Glass or similar hard materials. Ceramic media is a good choice when you must keep your media contamination to an absolute minimum and is ideal for milling individual chemicals.

Contact

AMIT 135: Lesson 7 Ball MillsCircuits Mining Mill

网页However, Morrell identified significant errors from this estimate when using small media sizes. Charged ball mill [image: (135-7-9)] Medium Charge Volume Fraction. The fraction of the mill volume occupied by the mill charge can be estimated based on a ratio of the cross-sectional areas.

Contact

Ceramic Ball Mill Lining BricksGrinding Media Duralox®

网页Duralox 92W lining bricks and Duralox 92W grinding media complement each other’s performance and best results are obtained when both are used together.. PHYSICAL PROPERTIES. Colour. White. Surface finish. Density. 3.70 ±

Contact

Ball Mills 911 Metallurgist

网页2017年2月13日 CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume.

Contact

Ceramic Ball Mill for Sale Buy Ceramic Ball Mill Machine

网页The ceramic ball mill uses a ceramic material liner, and ceramic alumina balls are used as grinding media. It is the key ball grinding mill equipment for fine grinding after the ceramic glaze is coarse grinding. The ceramic ball mill machine is widely used for the dry or wet grinding of the ceramic glaze mineral raw materials, such as feldspar, quartz, talc, kaolin,

Contact

Alumina Ceramic Grinding Media Mingxing

网页Alumina Ceramic Grinding Media are also suited for use in processes where mixing and dispersing effects play an important role. Media replacement and make-up charge levels drop significantly with the use of Mingxing Ceramics alumina grinding media. Alumina is the most common ceramic material used for ceramic grinding balls and ceramic ball mill

Contact