المنتجات الساخنة

A scale-up and design basis of continuous tube mills in cement

网页2020年3月1日 Eq. (18), representing the scale-up effect on the degree of size reduction, is examined with the cement mill data for both open and closed circuits.In Fig. 6, the left side of Eq. (18), the degree of size reduction, is plotted on the ordinate against the right side of

Contact

(PDF) Cement mill optimization: Design

网页1995年10月29日 The cement milling circuit can be seen as a two inputs/two outputs system. The designed multivariable control is based

Contact

Control System Architecture for a Cement Mill Based on

网页2015年2月14日 Costea et al. [13] developeda fuzzy logic-based control architecture in which the ball mill grinding process was considered as a single input and single output

Contact

Modern tube mill design and its influence on maintenance

网页1991年5月23日 The author discusses modern cement tube mill design features, taking into account new technical developments regarding bearing and drive train design. It is noted

Contact

Design and Realization Of Roller Mill Control System

网页2012年1月1日 a Distributed Control System(DCS) of cement raw materials is presented for the vertical roller mill by the application of ABB's IndustrialIT.

Contact

Predictive Controller Design for a Cement Ball Mill Grinding

网页Chemical process industries are running under severe constraints, and it is essential to maintain the end-product quality under disturbances. Maintaining the product quality in

Contact

(PDF) DYNAMIC DESIGN FOR GRINDING MILL

网页2019年1月30日 The diameter of grinding mills may be much large in mining industry. A practical case of ball mill foundation is examined herein. The diameter of mill is 8.0 m with length of 13.1 m, operating at

Contact

Engineering Design of Mechanical Equipment for

网页2017年5月1日 For fine grinding of cement clinker and additives, ball mills of various sizes are mostly used [1,2,6,7]. These grinding units are distinguished by the simplicity of their design, its operation

Contact

Digitization and the future of the cement plant McKinsey

网页2020年9月16日 According to our analyses, the cement plant of the future could reduce emissions by up to 75 percent by 2050 compared with 2017. Around 20 percent will

Contact

Design of clinker grinding system; mill and

网页Figure 1 presents the design of the clinker grinding system (closed circuit), which consists of a two-chamber ball mill and the separator (Plasari and T heraska, 19 81). Cement clinker is usually

Contact

PROCESS CONTROL FOR CEMENT GRINDING IN

网页2017年10月27日 Optimization of cement grinding using standard bond grinding calculations based on population balance models is successfully applied [4, 38]. Various grinding laws, energy relationships, control factors and controller design for cement grinding are discussed in [37]. Figure-1. Vertical roller mill for cement grinding [13].

Contact

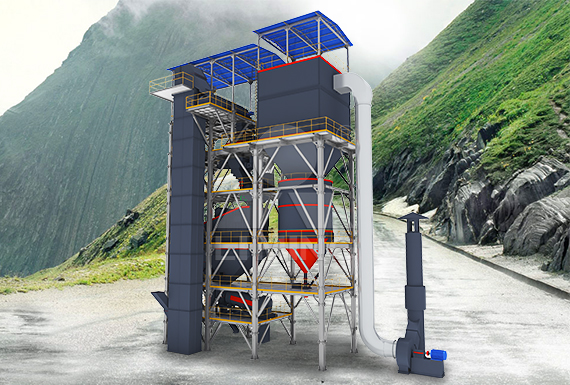

How to Start a Cement Factory DesignConstruction of Cement

网页A cement ball mill is ready for transportation. There are many kinds of industrial equipment used in a cement plant, including thermal equipment, grinding equipment, dust removal system, transportation system, storage system, and so on.When placing an order, we may need to order different equipment from multiple manufacturers at the same time.

Contact

Cemented paste backfill for mineral tailings management: Review and

网页2019年12月1日 This integrated CPB design system, though quite elusive at present, is possible after proper identifications of key factors that affect the performance of each process. In addition, non-linear relationships modelling directly from characteristics of starting materials to process performances is the crucial step for CPB design

Contact

(PDF) Grinding in Ball Mills: Modeling and Process Control

网页2012年6月1日 The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting ma terial (feeders), and the system for discharging the output product.

Contact

Large Cement Plant Design Principles AGICO Cement

网页The Design of Raw Material Grinding System. Cement plants are usually designed with raw material grinding systems with low energy consumption, especially the vertical roller mill (VRM), which is the first choice for large cement plants. Due to the large power consumption of large cement plants, the use of a vertical roller mill can obtain an

Contact

Digitization and the future of the cement plant McKinsey

网页2020年9月16日 According to our analyses, the cement plant of the future could reduce emissions by up to 75 percent by 2050 compared with 2017. Around 20 percent will come from operational advances, such as energy-efficiency measures and clinker substitution. An additional 10 percent will come from alternative fuels—however, the availability of

Contact

polysius® booster mill thyssenkrupp Polysius

网页Advantages at a glance: Modular design and small footprint enable integration in existing grinding plants. Production increase in range of 10-20 %, depending on the fineness, especially for smaller ball mill systems up to 100 tph. Quality improvement by use of the additional grinding stage, for example to improve the early strength while maintaining the

Contact

Cement Mill Process Requirement of Mill Motors Kiln

网页Power requirement is very high. Speed control ratio is 1:10. Very low creeping speeds of 1 rpm may be required. Starting torque should be in the range 200 to 250% of full load torque. The acceleration of the drive should be completed in about 15 s. For small periods an overload capacity of 200-250% may be required.

Contact

Cement Milll Separator Cyclone Air Separator in Cement Plant

网页Product Name: cement mill cyclone air separators. Capacity: 10 250 TPD. Condition: brand new. Airflow: 16000 240000 m3/h. SEND INQUIRY. Cement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plants. The function of the separator is to separate

Contact

Soft Sensor for Online Cement Fineness Predicting in Ball Mills

网页2020年1月1日 This stone is concerned with a comparative analysis of modern cement grinding systems, namely, combined grinding (Comflex®), high-pressure roll mill (HPRM) grinding, and horizontal roller mill

Contact